Karabudak Engineering Sanding Machines, Your Solution Partner in Wood Finishing; Karabudak Engineering has been producing furniture manufacturing machines of Turkish Engineering, which are renowned in Europe and America, since 2010. The company, whose brand awareness is increasing day by day, is the most preferred wood finishing machine manufacturer in Turkey with its Kama Machinery brand.

Known for its automatic wood painting machines and lines, Kama Makina offers suitable solutions for every business in the industrial sanding process. In addition to the standard wood sanding machines in its production, Kama Makina also produces machines for special surface treatments in specific projects. We have compiled the company’s most preferred standard business solutions for you.

Perfect Surfaces with Smart Sanding Machines

Kama KR YZM 1300 Surface Sanding Machine – Intelligent Process Technology

Karabudak Engineering Sanding Machines, Kama Machinery offers one of the most remarkable sanding machine solutions in its sanding lines with the KR YZM 1300 model. Equipped with image processing technology, YZM scans the surface down to the finest detail thanks to its special sensors. Thus, it makes it possible to sand parts with the same efficiency on carved and smooth surfaces.

Another feature of the KR YZM 1300 model, that has won the hearts of business owners, is a machine that uses the artificial intelligence and learning methods. Thus, you can select a specific area you want to process or adjust the treatment depth differences between the surfaces to be treated.

YZM 1300, a robotic arm with 8 orbital motors, allows you to adjust the pressure intensity and perform different operations on edges, low or high areas on a single piece. Thus, it helps you achieve optimization in which you can get the same result in every piece produced.

The features of the YZM 1300 automatic sanding machine are not limited to this. It enables raw and primer sanding with its oscillating disc brush system. In YZM 1300, which has 9 oscillating disc brushes, the height and speed of all discs are adjusted automatically.

Another feature that makes YZM 1300 powerful is its roller brush system, which allows raw and primer sanding on the product to be carried out in accordance with the smooth or uneven structure of the surface caused by carving. The oscillating roller brush system has two roller brushes that can be adjusted independently of each other.

In addition to these features, with its standard scotch roller system, the YZM 1300 automatic sanding machine removes the sanding marks of the finished products and helps you to obtain perfect surfaces by preparing a perfect ground.

The linear rails and bearings that enable the movement of the robot arms work integratedly with Kama Makina’s automatic lubrication system in YZM 1300 and ensure the equipment is automatically lubricated within certain periods. Thus, you do not need to bother with periodic oil maintenance of the machine. You can produce without any headache with a long-lasting and trouble-free performance.

You can easily clean sanding dust with the movable air jet unit.

Optionally, by integrating a cross brush system into the YZM 1300 automatic sanding machine, you can sand the CNC-made parts and rustic wooden parts in detail on the 2nd and 3rd axes.

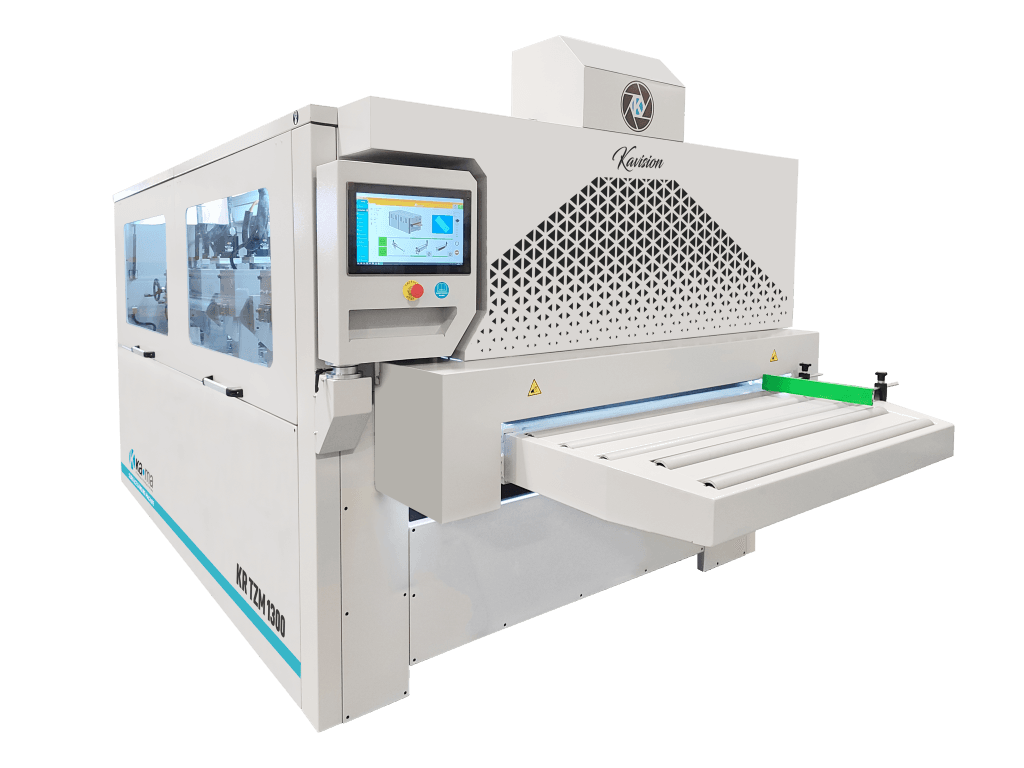

KR TZM 1300 Surface Sanding Machine – Your Machine for Precision Sanding

Karabudak Engineering Sanding Machines, Another machine that has a good reputation among smart sanding machines is the Kama KR TZM 1300 surface sanding machine. With image processing technology and sanding tasks given through 4 separate vibration arms, the arms provide orbital movement with a pressure sensitivity of 150 g and a speed of 12000 rpm, creating perfectly sanded surfaces.

Suitable Sanding Solutions for CNC Made Wood and Rustic Wood

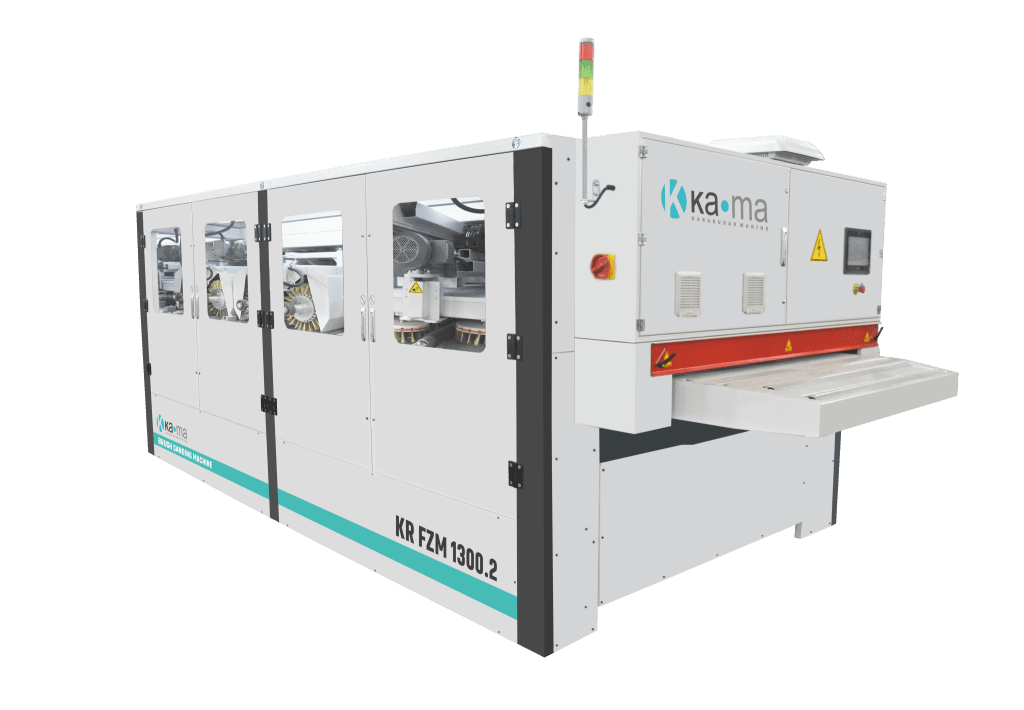

KR FZM 1300.1 and FZM 1300.2

Karabudak Engineering Sanding Machines, The company’s sanding machines also include special sanding solutions produced for sanding CNC parts and rustic wooden parts. KR FZM 1300.1 is one of these machines. KR FZM 1300.1, which is used for profile and wooden surfaces with its control system, oscillating sanding system and moving conveyor table, also has automatic lubrication and moving air jet unit like YZM.

In FZM 1300.1, where special production dimensions are possible, cross brush unit and vacuum table are offered as optional equipment. You can see the performance of FZM 1300.1, which is used as a door and cover sanding machine, in the company’s showroom by making an appointment with the company.

There is no technological difference between KR FZM 1300 – 1 and KR FZM 1300-2 automatic door sanding machines, but there is a difference in terms of parts. When switching between raw and primer sanding applications on the FZM 1300.1 sanding machine, the brush abrasives must be changed manually.

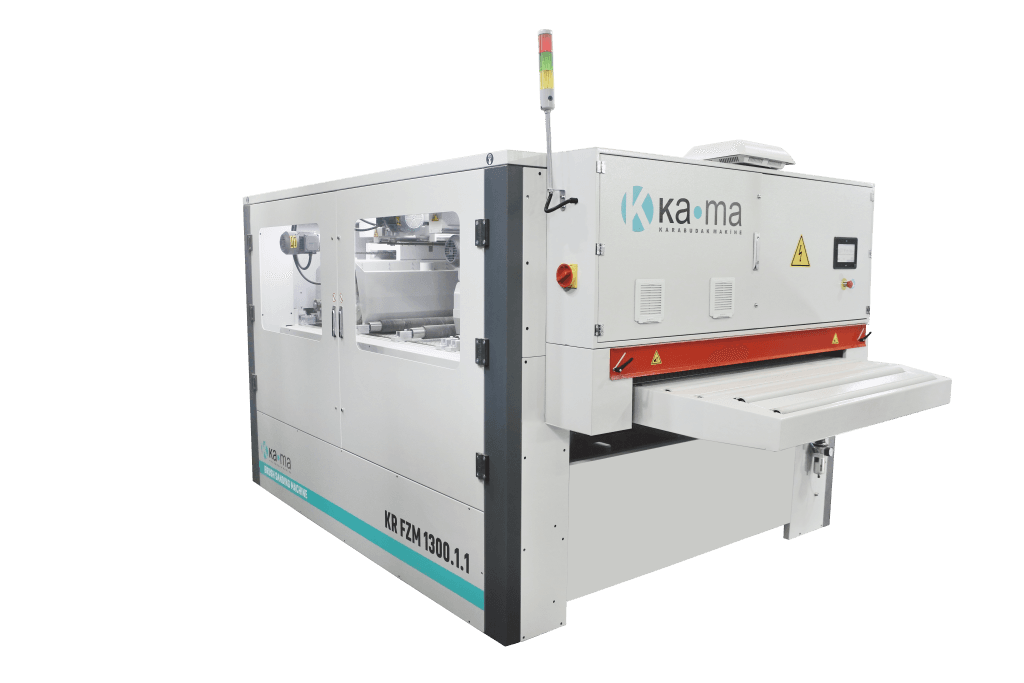

KR FZM 1300.1.1 – Your Practical Machine for Homogeneous Surface Sanding

Another technologically advanced example of automatic wood sanding machines is the KR FZM 1300.1.1 produced by Kama Makina. Developed as a solution to the need for three-dimensional raw and primer sanding in the processing of rustic and CNC carved surfaces, KR FZM 1300.1.1 wood sanding machine is used in every area where homogeneous surface sanding is required with its brush unit that operates vertically on the horizontal axis. In the model, which has the cross brush unit and a vacuum table as a regular part and order-specific expansion are offered as options.

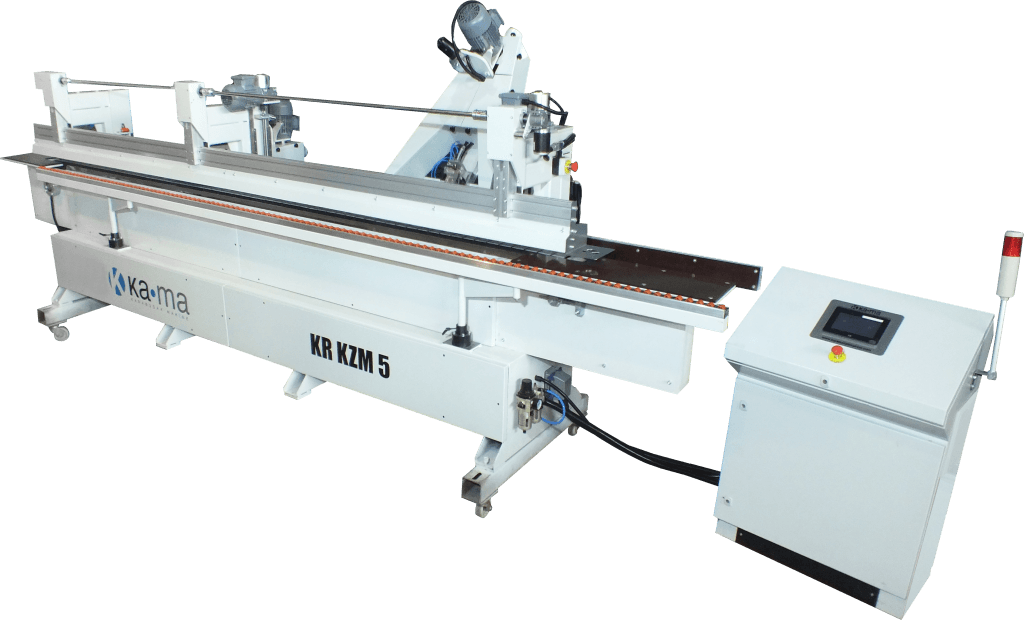

Sanding Technology for Door and Modular Furniture Edges

KR KZM 5 Edge Sanding Machine

Thanks to its flexible and mobile sanding units, it performs raw and primer sanding of flat, chamfered and radiused edges to produce a perfect finish. Produced as standard with flexible belt sander, oscillating orbital sander, disc brush sander, scotch mop and control system, KR KZM 5 is customized with options such as extra flexible belt sander unit and extra cylindrical brush sander.

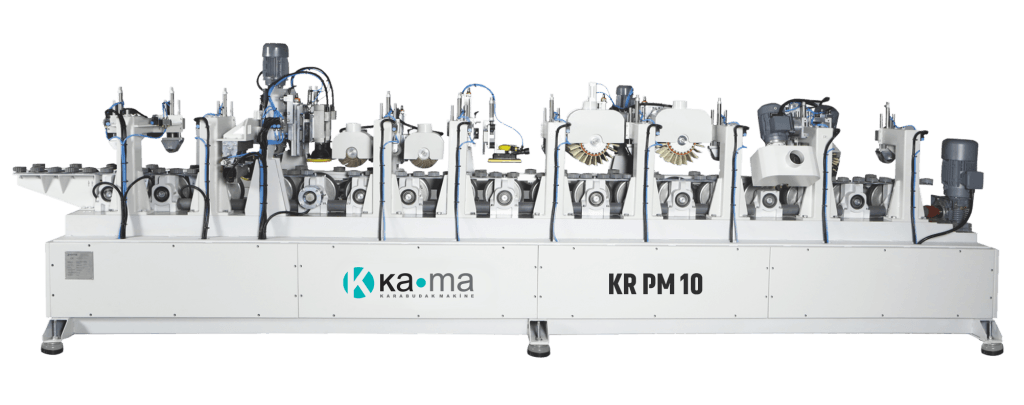

KR PM 10 Profile Sanding Machine – Sander for Door Frame, Molding and Skirting Profiles

KR PM 10, a sanding machine designed for raw and primed surfaces of door frames, moldings and baseboards, recognizes the starting and ending points of part printing. KR PM 10 profile sanding machine, consisting of oscillating orbital edge sander, oscillating orbital surface sander, rectangular vibratory sander, oscillating cylindrical brush sander, fixed cylindrical brush, mop sander and control system, is the machine with the highest edge surface processing ability among the oscillating sanding machines. It is suitable for use in casings, moldings, skirting boards, crowns and all other types of edge wooden profiles.

KR KUVM 2L Edge UV Applying and Sanding Machine

Innovation in Sanding Technology: Edge UV filler, UV Primer and Sanding Machine

Damaged surfaces caused by excess paint absorbed due to the soft fiber structure on the edges during painting processes on MDF parts are history with KR KUVM 2L. Paint or varnish is applied to the MDF edges, which are sanded between special sandpaper grit values, and the area where the varnish is applied is instantly exposed to UV drying. Thus, none of the problems related to the part absorbing too much paint and bleeding paint will occur on the part.

Among the company’s smart and automatic painting machines and systems for painting processes after sanding, Kbotic, which performs self-quality control, and Cevval, which offers excellent performance in automatic lacquer varnish spraying, are the most preferred products in Europe.

Among Kama Makina’s highly qualified woodworking machines, the sanding group includes many more products worth exploring. You can visit the company’s website for edge sanding machines, cover sanding machines, profile painting and sanding lines and machines, or other types of wood sanding machines specific to your needs.

blackbudak machine, dyeing machine, sanding machine, uv drying, wedge, wedge machine, wood finishing machines, wood painting machines, wood processing machinery, wood processing machines, wood sanding machines, woodworking machinery, woodworking machinery prices, woodworking tools